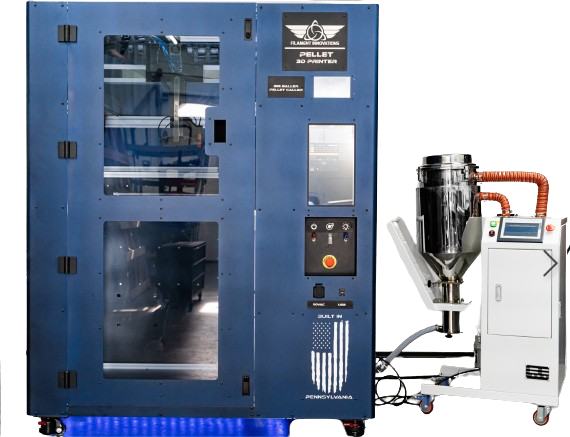

Filament Innovations ICARUS-GEN6 3D Printer Pulsar Pellet Drive

Entering its sixth generation, the newest ICARUS is faster, cleaner, and easier to use than ever.

If you are in the Prosthetics and Orthotics Industry, the ICARUS is the ultimate choice for check socket fabrication with below the knee sockets 3d printed in just 45 - 90 minutes.

With an average wieght of 525 - 550g, PETG check sockets can be 3d printed for less than $20 each.

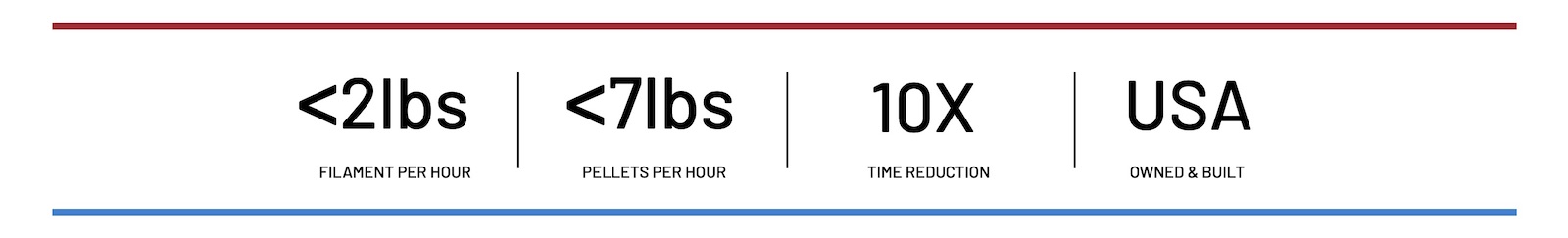

The Sixth generation ICARUS features a fully enclosed 17.7 x 17.7 x 37.2 inch build volume with Typhoon high-flow filament extrusion at nearly 2lbs per hour, a 450ºC max nozzle temperature, 120ºC max bed temperature, and a Four Z Axis Tilt & Mesh Bed Levelling System.

What's new for the Sixth Gen?

Laser Scanning Assistance

Over the years of building 3D Printers, we hear it from our customers: "How do I get the perfect first layer?". Well, what if a precise laser would measure your first layer and compensate as needed? That is exactly what Filament Innovations and Ahead Wind have worked on for the newest ICARUS. Every sixth generation ICARUS ships with a laser scanner to measure your first layer and adjust the bed height as needed, to get the perfect first layer.

Linear Motion

For accuracy and safety, enclosed ballscrews are used on the X,Y, and Z axis of the entire machine. You won't find a belt on this machine. All of this, combined with USA Made servo motors from Teknic on all three axis, ensure precise motion movement.

Electrical Requirements

The sixth generation ICARUS is available in either a 220VAC Single Phase 30amp circuit (suggested for the pellet version), or a dedicated 110VAC 15amp circuit (suggested for the filament version). As a pellet dryer is strongly recommended for the pellet version of the machine, the pellet dryer conveniently plugs into the side of the ICARUS, so one 220VAC receptacle can run the entire pellet printing process.

Extrusion System

Choose your extrusion system! Our complete integration of the Dyze Design Pulsar (FGF Pellet system) or the Typhoon (FDM high-flow Filament system) means yours ICARUS can be customized to your needs! If you are interested in pellet, please note that you, the customer, must supply a 100psi compressed air line.

Fully enclosed ballscrews, closed-loop Leadshine stepper motors, and on-board water cooling deliver an easy to use 3D Printer with less maintenance from an American company.

Key Features:

- Filament Output: <2lbs per hour

- Build Area (W,D,H - mm): 450 x 450 x 945

- Extrusion System: Pulsar Pellet Drive

- Filament Diameter: 2.85mm

- Real Printed Accuracy: ~100 microns

- Breaker Requirement: 15amps on 110VAC

For more information or to set up a free consultation please contact us.

We'll gladly provide a sample 3d printed check socked for testing, or send us your .stl files for estimated print times and material costs.

Email: [email protected]

Phone: (800) 201-3249

Typhoon 2.50mm Nozzle High-Flow Extrusion

- Machine Size (W,D,H): 60"x34"x75"

- Build Area (XYZ): 450mm x 450mm x 945mm

- Weight: 500lbs

- Motors: USA Made Servo Motors

- Extrusion: Pulsar Pellet

- Motion: TBI Enclosed Precision Ballscrews

- Print Surfaces: PEI, BuildTak, Steel

- Print Plate: Magnetic Spring Steel

- Build Plate: 3/8" MIC-6

- Max Nozzle Temp: 450C

- Heated Bed: 120C

- Temperature Probe(s): PT100

- Print Monitoring: Orthus - Jam & Runout

- Bed Leveling: Four Z Axis Tilt & Mesh

- Laser Scanning: First Layer Scan

- Electronics: Duet 3 Ecosystem

- Power: 110VAC or 220VAC

- Slicer: Simplify3D

- Touchscreen: 7" x 15"

- Filament Type: PLA, PETG, ABS, Nylon, TPU, TPC, ASA, PVA, HIPS, BVOH, PC, PET, Carbon Fiber Reinforced, Fiber Reinforced, Wood Reinforced, etc.

Please note - all machines are built to order with a four to six week lead time. Need it sooner? Please contact us to see how we can accomodate you. Shipping is handled via FedEx freight and the prices above do include LTL Freight shipping. If you need liftgate service then please contact us.

We pride ourselves on providing outstanding client service, and are always available for a discussion, either by phone or via email.

Email us: [email protected]

Call us: (800) 201-3249

Every 3D Printer purchase from 3D Printlife includes a free Intro to Digital Design online course from the New Collar Network. Learn the basics of Computer Aided Design [CAD] modeling with free on-line software. Automatically included at checkout.

3D Printlife is committed to improving sustainability in 3D printing, our 3D filaments are compatible with your 3D Printer or 3D Pen, and we stock both 1.75mm & 2.85mm. Featuring materials from FormFutura, Filamentive, 3DXTECH, Copper3D, & Keene Village Plastics, our 3D filaments are biodegradable, eco-friendly, tough materials and feature cardboard spooling to help offset your carbon footprint, and are modified and optimized for 3d printing including PLA, PLAyPHAb PLA/PHA, PVA, Enviro ABS, Bio PETG, ALGA algae based PLA, Nylon like DURA, ABS like OMNI, semi flexible YOGA TPU replacement, RePLAy 100% recycled PLA filament, Carbon Fibre, ASA, Polypropylene, PEEK, Carbon Fiber PEEK, PEKK, PEI Ultem, and PPSU. Use your 3D Scanner or your imagination to help create your 3D printed parts. Our sustainable 3D filaments are compatible with FDM 3D Printers including Dremel, Raise3D, Flashforge, Artillery, Bambu Lab, Creality, XYZPrinting, QIDI, Syndaver, Robo3D, Prusa, Snapmaker, Monoprice, Lulzbot, MakerBot, and Ultimaker.

| Title | Filament Innovations ICARUS-GEN6 3D Printer Pulsar Pellet Drive |

|---|---|

| Manufacturer | Filament Innovations |

| Build Volume (Inches) | 17.7 x 17.7 x 37.2 |

| Maximum Nozzle Temp | 450ºC |

| Max Build Plate Temp | 120ºC |

| Extruders | Single |

| Enclosure | Enclosed |

| Bed Leveling | BLTouch: Mesh Levelling System |

| Build Plate Material | Flexible, Removable, Powder-Coated PEI |

| Touch Screen | ✓ |

| Heated Bed | ✓ |

| Filament Run-Out Sensor | ✓ |

| Flexible Build Plate | ✓ |

| HEPA Filter | ✓ |

| Camera | ✓ |

| Supported Materials | 40 Plus |

| Connectivity | Wi-Fi, Ethernet, USB |

| Max Print Speed | 150mm/s |

| Layer Height | 100 microns |

| Software | Simplify3D |

| Physical Dimensions | 60 x 34 x 75 Inches |

| Filament Diameter | 2.85mm High-Flow Typhoon |

| MPN | ICARUS-GEN6 |

| Weight lbs | 500 |

| US Based Support | ✓ |

| Warranty | 1 Year |