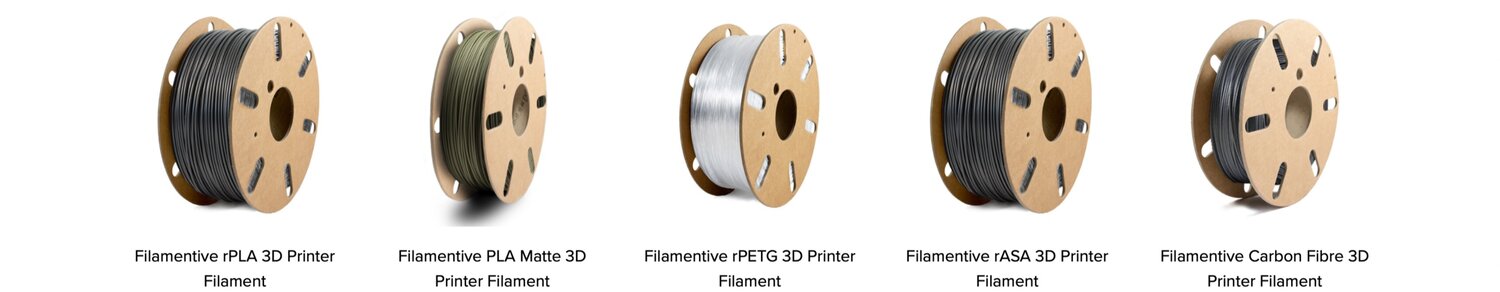

High Quality Recycled 3D Printer Filament

NOW AVAILABLE IN THE US!

3D Printlife is proud to introduce Filamentive’s innovative line of sustainable 3d print materials to the US market. Filamentive’s commitment to sustainability and quality in 3d printing is exemplary and we have admired their brand since its inception. Based in the UK, winners of businessgreen.com’s award for Circular Economy Technology of the Year, Filamentive is one of the leading filament producers in Europe, and we are truly excited to offer their filaments to our customers!

SHOP FILAMENTIVE MATERIALS HERE

To learn more visit: www.filamentive.com

Where possible, recycled materials will be used to produce Filamentive 3D printer filament, in accordance with ISO 14021:2016;

Post-consumer recycled material: Material generated by households or by commercial, industrial and institutional facilities in their role as end-users of the product which can no longer be used for its intended purpose. This includes returns of material from the distribution chain.

Pre-consumer recycled material: Material diverted from the waste stream during a manufacturing process.

Material sourcing

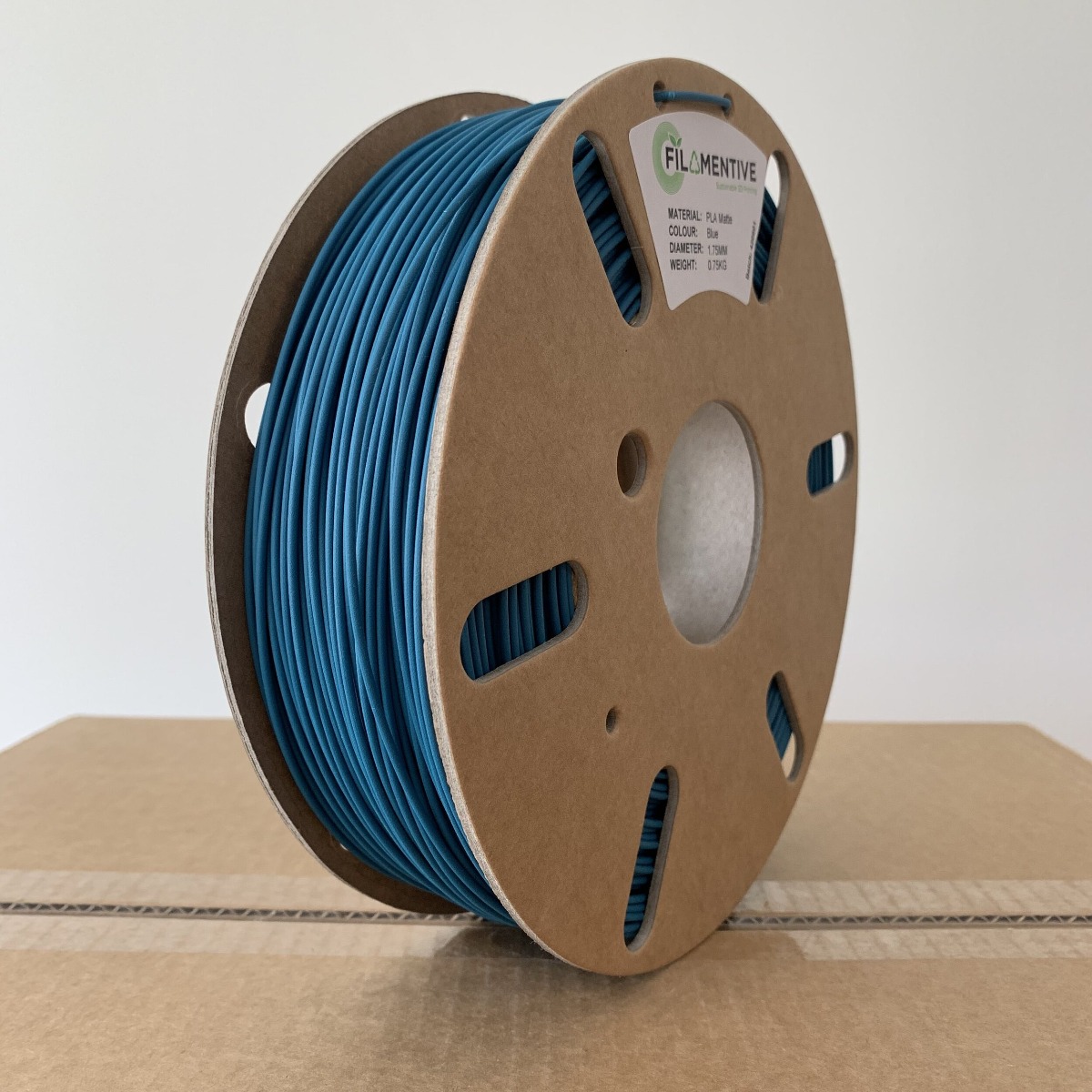

A careful selection criteria is in place in order to guarantee quality, consistent waste streams. Filamentive uses both post-consumer waste – such as recycled PET bottles, as well as post-industrial waste – such as material diverted from the waste stream during a manufacturing process, which is used to produce their PLA filament.

Manufacturing

Plastic filament for 3D printers is produced by a process known as plastic extrusion. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into a die, which shapes the polymer into the shape of filament – typically either 1.75mm or 2.85mm in diameter. The extrusion work is currently outsourced to our specialist producer who are able to guarantee quality, consistency and manufacturing at scale.

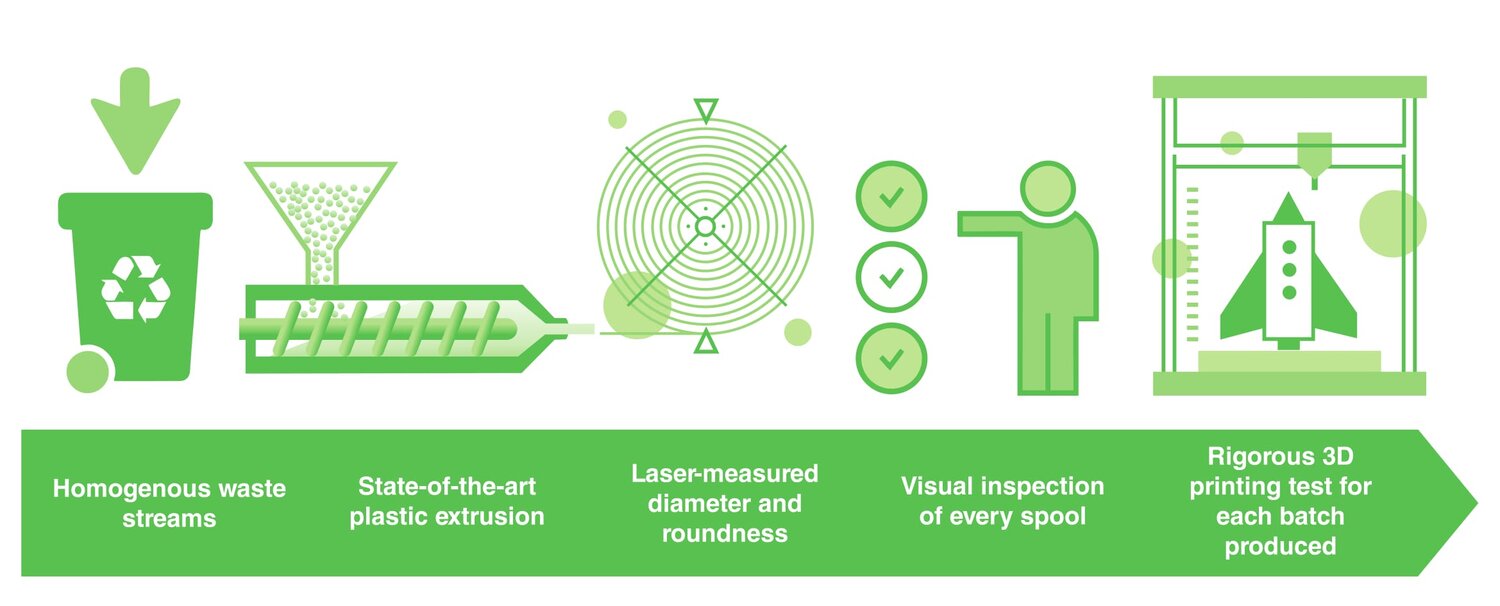

Quality assurance

All feedstock streams are meticulously checked to ensure homogeneity. During extrusion, filament is measured by lasers from 2-axes, with an alarm bell sounding if the diameter falls outside our high standards. Filament is then wound onto bulk spools for visual inspection before it is put onto the individual spools to be packaged. Each batch produced undergoes a rigorous 3D printing test; if Filamentive is not happy with the print quality then it won’t leave the factory, simple as that.

This results in:

-

NO loss of mechanical properties

-

±0.05mm diameter tolerances

-

Minimum of 95% roundness

Filamentive doesn’t stop at the filament itself – they also use 100% recyclable cardboard spools as well as recyclable cardboard packaging. Sustainability is key to their business model and Filamentive continues to reduce their environment impact with new products and initiatives.